Titanium Basics

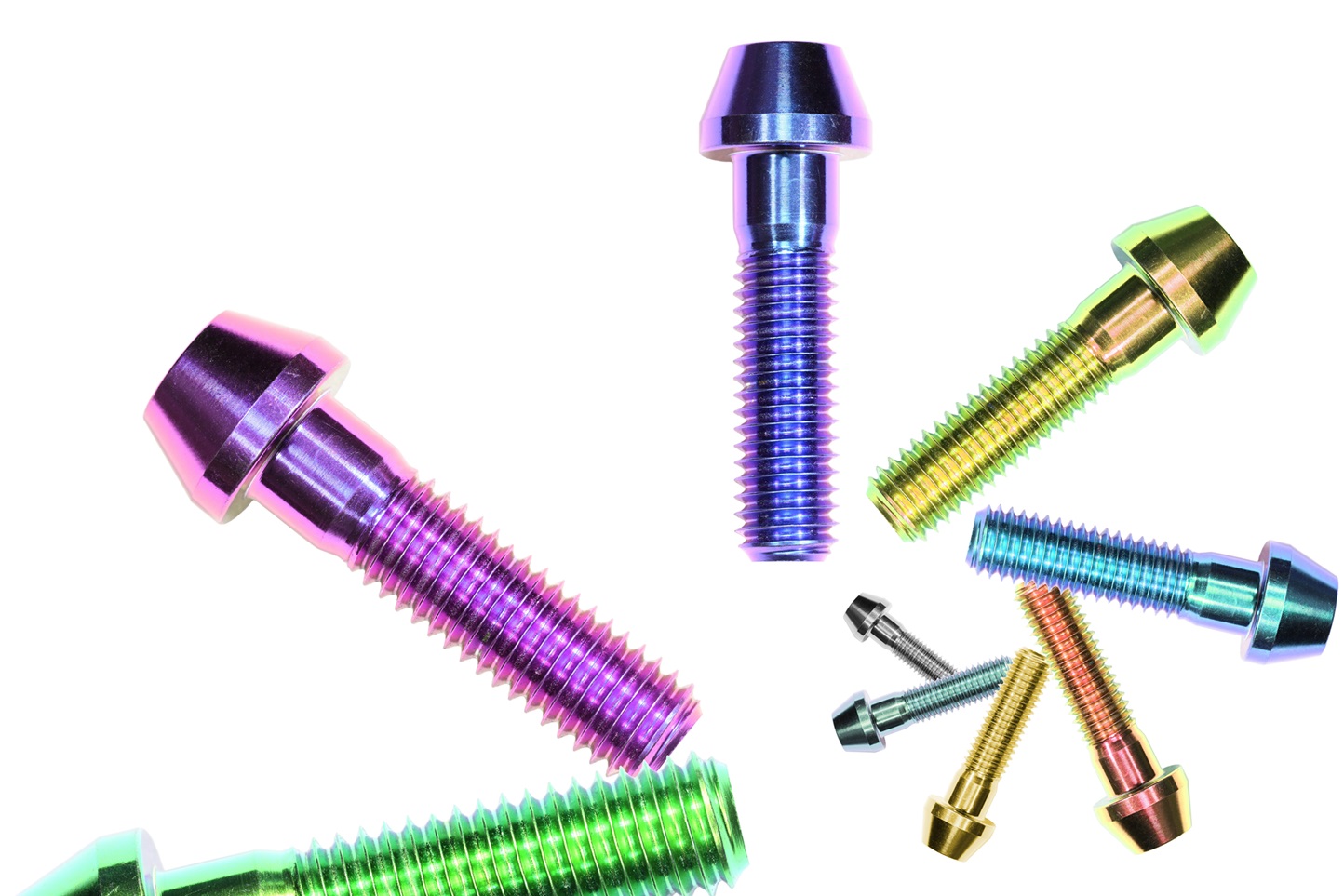

Titanium anodizing is a surface treatment process that enhances the metal’s natural qualities, creating a durable and vibrant finish. Through anodizing, a thin oxide layer forms on the metal surface when exposed to an electrical current.

How Does the Anodizing Process Work?

The anodizing process involves placing the titanium part in an electrolytic bath, usually consisting of sulfuric acid, and applying a controlled voltage. This voltage causes the titanium to act as the anode, resulting in the formation of a titanium dioxide (TiO₂) layer. By adjusting the voltage, different oxide layer thicknesses are created, producing a spectrum of colors.

Anodized Titanium Color Chart and Voltages

Understanding the relationship between voltage and the colors of titanium is key when working with anodized parts. Below is a simplified titanium anodizing chart showing how different voltages correspond to various anodized titanium colors:

| Voltage | Color |

| 5V | Gold |

| 20V | Purple |

| 30V | Blue |

| 60V | Orange |

| 75V | Pink |

| 90V | Blue |

| 110V | Green |

Why Choose Titanium for Projects?

Titanium stands out compared to metals, like steel and aluminum due to its exceptional properties. It’s nearly as strong as steel but much lighter, making it ideal for weight-sensitive applications.

Titanium is also highly corrosion-resistant, which is why it’s often used in harsh environments where other metals might degrade. Unlike steel, titanium doesn’t rust, and it has a higher melting point than aluminum, making it more suitable for high-temperature applications.

Safety Considerations in the Anodizing Process

Due to the involvement of acids and electrical equipment, anodizing titanium requires specific safety measures. The process should be handled in a well-ventilated area, using protective gear such as gloves, goggles, and aprons.

Titanium vs. Other Metals: Why It’s Ideal for Anodizing

Anodizing is a popular surface treatment for several metals, but it’s especially effective with titanium. Steel and aluminum can be anodized, too, but the results are quite different. Anodized steel, for instance, is mostly used for anti-corrosion coatings, and anodized aluminum is more common for decorative purposes.

In contrast, anodized titanium achieves vibrant, durable colors without compromising on structural integrity. The color consistency and range with titanium are far superior, thanks to the metal’s unique reaction to voltage changes.

Applications of Anodized Titanium

Anodized titanium’s unique blend of beauty and resilience makes it a go-to material in a variety of industries. In aerospace, anodized titanium is used in components exposed to high temperatures and corrosive environments, making it a perfect choice for fastening elements.

In the medical field, anodized titanium is often chosen for implants and surgical instruments due to its biocompatibility and wear resistance. Jewelry designers appreciate anodized titanium for its vibrant hues and hypoallergenic properties.

At the same time, automotive enthusiasts use it in custom exhaust tips, shift knobs, and interior trims to add a personalized touch. Each of these industries benefits from the durability and aesthetic versatility that anodized titanium offers.

Conclusion: The Versatility and Value of Titanium Anodizing

Titanium anodizing stands out as a remarkable process that enhances titanium's already impressive properties. Through controlled oxidation, it creates a spectrum of vibrant, durable colors while maintaining the metal's inherent strength and corrosion resistance.

From aerospace and medical applications to jewelry and automotive customization, anodized titanium offers unparalleled versatility. Its biocompatibility, lightweight nature, and resistance to harsh environments make it an ideal choice for demanding applications.

As we've explored, the anodizing process while requiring careful handling and safety precautions, results in a product that excels in both form and function, solidifying titanium's position as a premier material in modern manufacturing and design.

Frequently Asked Questions

What color is titanium in its natural state?

What is the color of titanium? Titanium, in its natural state, appears as a silvery-gray metal, sometimes described as having a matte sheen. It doesn’t have the vibrant anodized hues until the anodizing process is applied.

Is anodizing titanium safe for health-related applications?

Yes, anodized titanium is considered safe for health-related uses like surgical implants and dental tools because the oxide layer is non-toxic, non-reactive, and biocompatible.

Does the color of anodized titanium fade over time?

The anodized layer on titanium is highly durable and resistant to fading under normal conditions. However, exposure to extreme abrasion or harsh chemicals can wear down the oxide layer, potentially altering the color.

Why don’t other metals show similar vibrant colors?

The unique color spectrum in anodized titanium is due to light interference within the oxide layer, which depends on its thickness. Other metals don’t produce such interference patterns, limiting their color range.

Disclaimer

Anodizing titanium involves hazardous chemicals and high voltage, which can be dangerous without proper knowledge and equipment. DIY attempts are strongly discouraged. Always seek professional services to ensure safety and achieve the best results.