Deck Screws vs Construction Screws: How to Choose

Scrolling through pages of screws online, unsure what to add to your cart? Or standing in the fastener aisle of your local hardware store, staring at boxes of screws?

If choosing between deck screws and construction screws feels like a bigger challenge than the project itself, rest assured you aren't alone. While they might look similar at first glance, choosing the wrong one could mean the difference between a lasting result and a do-over.

But the good news is once you understand the differences, selecting the right screw becomes second nature. In this guide, we'll cut through the confusion so you can choose with confidence.

Whether you're building a deck that needs to weather the elements or handling indoor or outdoor construction projects, we'll help you pick the right fastener for the job.

Screw Basics 101: Terminology

Before we sort out deck vs construction screws, let's get familiar with the language. Understanding these basics will make every hardware store run easier and help you nail the right choice for all your projects.

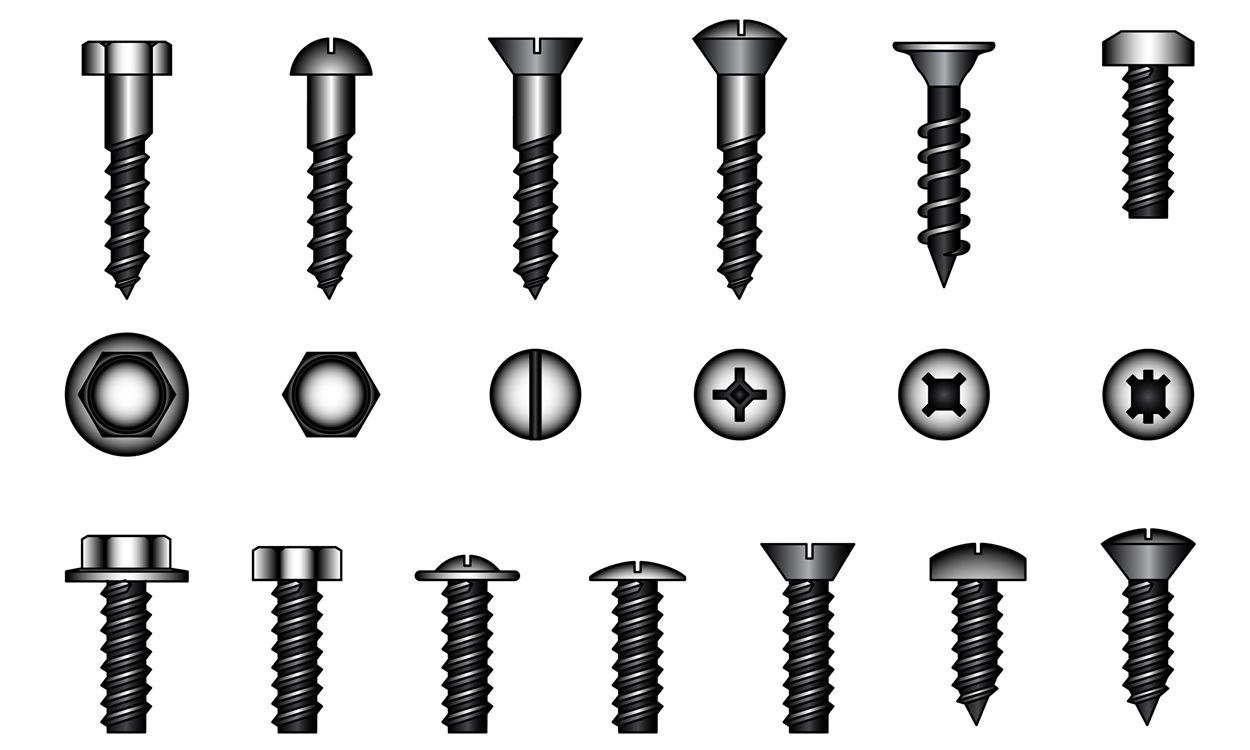

Head Types and Drive Patterns

The screw head and its drive pattern determine how the screw is installed. Common types include Phillips (the classic cross pattern), square drive (popular for deck screws), Torx (star-shaped, great for power tools), and combo drives that work with multiple driver types.

Some heads sit flush with the surface (countersunk), while others have a flat underside to hold materials together (washer heads).

Thread Design and Pitch

Threads as the spiral pattern wrapping around your screw. Coarse threads have deeper, more spaced-out spirals - perfect for softwoods and outdoor projects. Fine threads are closer together and work better with hardwoods and metal. The thread's pitch (distance between spirals) affects how quickly and firmly the screw bites into your material.

Shank Characteristics

The shank is the main body of your screw. Some have a smooth section near the head (unthreaded portion) that allows for better movement between joined materials. Others are fully threaded for maximum grip. The shank's diameter affects the screw's strength and the size of pilot hole you'll need.

Tips and Points

Screw tips come in several styles. Sharp points are great for general use, while self-drilling tips have tiny cutting edges for metal. Type 17 points (also called auger tips) excel in wood, cutting their own path to reduce splitting. The right tip can eliminate the need for pilot holes in many cases.

Coatings and Finishes

Coatings protect your screws from corrosion. Zinc plating offers basic rust resistance for indoor use. For outdoor projects, look for galvanized coatings or stainless steel.

Now that you're up to speed on screw speak, Let's get to the good stuff - what makes deck screws and construction screws different. We’ll start with deck screws.

Deck Screws Overview

Here's why deck screws earn their spot in your toolbox. Made typically from stainless steel or coated carbon steel, these screws are built to handle whatever Mother Nature throws at them. They're the go-to choice for outdoor projects thanks to their corrosion resistance and weatherproof design.

The magic is in the details: deck screws feature sharper threads than standard wood screws, which helps them bite into treated lumber without stripping.

Most come with a special coating that prevents rust and staining—this is needed when working with pressure-treated wood. You'll usually spot them with a bugle head (that slightly curved area under the head), which lets them sit flush without splitting your deck boards.

Size-wise, you'll find them anywhere from 1" to 6" long, with 2-1/2" and 3" being the most popular for deck boards. The thicker shank means better hold, while the coarse threads give you that solid grip you need when securing deck boards or handling outdoor construction.

Fasterene Deck Screws

For a reliable deck build, choosing quality screws is essential. Our deck screws are available in corrosion-resistant 18-8, 305, and 316 stainless steel.

Pro tip: Building near the coast? Step up to 316.

Even though they’re called deck screws, don't let that limit you - these are perfect for all sorts of outdoor projects. Keep some handy for fences, docks, pergolas, garden beds, or any project where wood meets weather.

Construction Screws Overview

Construction screws are engineered for serious heavy-duty applications. Anywhere you need maximum holding power. Unlike deck screws, these beefier fasteners are all about strength and structural integrity.

Notable features include the thicker shank for superior shear strength and aggressive threads that power through tough materials.

Construction screws typically come with either Torx (star-shaped) drive or square drive patterns. The Torx drive, in particular, is preferred for construction screws as it provides excellent driver bit engagement and resists cam-out (slipping) even under high torque. Some also feature combination drives that work with multiple driver types.

You'll find these workhorses in lengths from 2" to 8", with hefty shank diameters to match their heavy-duty purpose.

The threads are engineered differently, too - they're designed to draw materials together with serious clamping force, just what’s needed when joining multiple layers or needing that extra structural strength.

Indoor vs Outdoor Construction

For indoor framing and structural work, zinc-plated carbon steel construction screws are your go-to. They're perfect for:

- Floor joist installation

- Wall framing

- Installing heavy cabinets

- Structural repairs

- Stair construction

- Subfloor installation

Take the project outside, and you'll want coated or stainless versions that can handle the elements. Outdoor construction screws need to juggle two jobs - providing serious structural strength while fighting off rust and corrosion. Look for options with advanced coatings or stainless steel construction for:

- Structural pergolas

- Heavy-duty fence posts

- Outdoor stair stringers

- Retaining walls

- Timber frame construction

Fasterene Construction Screws

When it comes to indoor construction - whether you're framing, laying subfloor, hanging cabinets, or working with drywall - you need screws that won't let you down.

Our lineup includes Flat Head Wood Screws that sit flush and grip tight for all your structural woodwork, Self-Drilling Screws that make light work of metal-to-wood connections, and Pan Head Machine Screws for those heavy-duty bracket and hardware installations.

Good fasteners make good projects - it's that simple.

| Deck and Construction Screws Side-by-Side Comparison | ||

|---|---|---|

| Feature | Deck Screws | Construction Screws |

| Primary Use | Outdoor projects, decking, fencing | Structural work, framing, heavy-duty joints |

| Material | Stainless Steel | Hardened Steel |

| Thread Design | Sharp, coarse threads for treated lumber | Aggressive threads for clamping force |

| Head Type | Typically bugle head | Various, often Torx or square drive |

| Best For | Projects exposed to weather | Load-bearing connections |

Structural Screws vs. Deck Screws

These heavy-duty fasteners are specifically engineered and tested for load-bearing connections - think beams, joists, and other crucial structural elements. Unlike deck screws, structural screws often come with an evaluation report (like ICC-ES) that confirms their strength ratings and approved uses.

Structural screws typically feature:

- Higher shear and tensile strength ratings

- Specific thread designs for maximum holding power

- Often can replace traditional lag bolts and thru-bolts

- Available in larger diameters and lengths

While deck screws excel at securing deck boards, and construction screws handle general building tasks, structural screws are your go-to when you need serious structural strength that meets building code requirements.

Making the Right Choice

Now that you know the differences between deck and construction screws, choosing the right one comes down to three main factors:

Materials

- Pressure-treated lumber? Go with deck screws - their coating won't react with the chemicals in the wood

- Working with hardwoods? Construction screws have the muscle you need

- Metal-to-wood connections? Look for self-drilling construction screws

- Multiple layers of material? Construction screws excel at pulling everything tight

Your Environment

- Near the coast? Choose 316 stainless deck screws

- Standard outdoor projects? 305 stainless deck screws will do the job

- Wet areas inside (like bathrooms)? Consider corrosion-resistant options

Project Requirements

- Need structural strength? Construction screws

- Want weather resistance? Deck screws

- Both? Go with outdoor-rated construction screws

Get started Today

Now you know the differences between deck and construction screws and can choose with confidence. Your deck will stand up to years of family barbecues, and your structural work will stay rock solid - all thanks to picking the right screws for the job.

Make Fasterene your one-stop shop for all your indoor and outdoor fastening projects. We've got you covered with quality screws you can trust.

Browse our Full Range of Fasteners

Still unsure and need help choosing? Have questions about a specific project? Get in touch - we're here to help.