Blind (POP) Rivets 101

If you've ever worked with blind rivets, you may wonder, “What is a blind rivet?” We are about to explore a range of different aspects of blind rivets, including the difference between blind rivets and pop rivets, blind rivet installation, and how blind rivets work. Continue reading to find out more about blind (POP) rivets!

What is a Blind Rivet?

Blind rivets, or pop rivets, sometimes referred to as blind pop rivets, are specially designed fasteners used when access to the back or rear of the joint is limited.

Their construction is two-part, consisting of the rivet body (which may also be known as a shell or hat) and the stem (generally called a mandrel).

In this photo, the body of the rivet is before the circular ring, and the mandrel is after it. When you purchase blind rivets, the entire fastener is ready for use.

How do Blind Rivets Work?

When using blind rivets as a fastener, you need to use a special tool known as a riveting tool or rivet gun to install them. Blind rivet installation involves pre-drilling a range of holes in the item you’ll be fastening to another surface.

The blind rivet is then placed inside the hole (which goes through both surfaces that you’re attaching to each other), and the rivet gun is used to draw the mandril.

The riveting tool pulls on the stem of the rivet, causing the hat to flatten, which effectively attaches the two surfaces to one another. Generally, the mandrel is either designed to have a bulge that cannot pull through the hat (resulting in the hat pulling flat) or is simply attached to the hat somehow.

As soon as the hat is flattened, the rivet's stem breaks off, leaving a smooth surface.

Common Applications for Blind Rivets

If you’ve been trying to understand the difference between a blind rivet vs. a pop rivet, rest easy, as they’re exactly the same thing. While the two terms may be slightly confusing at times, these fasteners remain incredibly easy to use, resulting in a wide range of different applications and uses.

One of the many advantages of blind pop rivets, which results in this wide variety of applications, is the fact that they aren’t material-specific. They can combine two entirely different materials into a fastened entity. From wood to sheet metal and many other materials, rivets are easy to use and versatile.

Essentially, pop rivets may be used anywhere a strong permanent fastener is required and the materials being fastened are fairly thin.

One common application is joining sheet metal. In some places, you may also see pop rivets used to install license plates. Bodywork on vehicles, certain DIY applications (including jeans, in some instances), HVAC installations, submersibles, and small electronics are just a few more examples.

How to Install a Blind Rivet

When using these fasteners, knowing how to use blind rivets becomes essential. In essence, the process is incredibly simple. The key is to ensure that you’re fastening the right kinds of materials and that you buy an appropriate rivet size with the right grip range (more about that later).

Here’s a quick guide to the actual installation process in an easy-to-follow step-by-step format:

- Step One: Drill a hole through the upper material and down into the lower material, ensuring that it falls in the exact place where you want to install the rivet.

- Step Two: Choose a rivet of the appropriate size and place it into the hole you’ve just created.

- Step Three: Cover the rivet's mandrel with the riveting tool or rivet gun, ensuring that the mandrel is properly aligned within the tool.

- Step Four: Use the tool to install the rivet. This typically means squeezing the handle mechanism to pull on the mandrel and lock the rivet into place.

- Step Five: Remove the riveting tool and dispose of the mandrel.

- Step Six: Ensure that your rivet is a snug fit. If you’ve chosen the appropriate size rivet for your application, it will hold tightly to both materials, forming a permanent joint.

- Pro Tip: If the hole is too big, the rivet will fit loosely inside it, resulting in a rivet that spins and moves about. If the hole is too small, the rivet will be seated badly and not create a proper seal.

Congratulations—you’ve successfully installed the rivet! You can repeat the above steps as often as necessary until your entire application is appropriately fastened.

You can also use it on as many different types of materials as you like, as long as you ensure that the materials are of the appropriate type.

Rivet Sizes & Grip Range

When looking for the appropriate rivet for your application, there are two basic things about sizing that you need to know.

The first is the rivet size, which relates directly to the size of the hole you need for the rivet. The second is the grip range, which determines how thick the material you can fasten with the rivet.

Rivet Size Charts

Here’s a convenient chart listing the sizes and grip ranges of different rivet series. Specific rivet numbers within each series will have specific grip ranges, those are listed in the second chart.

|

Rivet Series |

Nominal Size (in) |

Hole Size Range (in) |

Rivet Grip Range (in) |

Body Length (in) |

|

3 |

3/32" |

0.100-0.097 |

0.020-0.125 |

0.25-0.75 |

|

4 |

1/8" |

0.133-0.129 |

0.020-0.625 |

0.212-1.025 |

|

5 |

5/32" |

0.164-0.160 |

0.063-1.125 |

0.300-1.300 |

|

6 |

3/16" |

0.196-0.192 |

0.020-1.375 |

0.325-1.575 |

|

8 |

1/4" |

0.261-0.257 |

0.020-1.500 |

0.375-1.750 |

|

Rivet # |

Grip Range |

Rivet # |

Grip Range |

Rivet # |

Grip Range |

Rivet # |

Grip Range |

Rivet # |

Grip Range |

|

3-2 |

0.020-0.125 |

4-1 |

0.020-0.062 |

5-2 |

0.063-0.125 |

6-2 |

0.020-0.187 |

8-2 |

0.020-0.125 |

|

3-4 |

0.126-0.250 |

4-2 |

0.063-0.125 |

5-3 |

0.126-0.187 |

6-3 |

0.126-0.187 |

8-4 |

0.126-0.250 |

|

3-6 |

0.251-0.375 |

4-3 |

0.126-0.187 |

5-4 |

0.188-0.250 |

6-4 |

0.188-0.250 |

8-6 |

0.251-0.375 |

|

3-8 |

0.376-0.500 |

4-4 |

0.188-0.250 |

5-6 |

0.251-0.375 |

6-6 |

0.251-0.375 |

8-8 |

0.376-0.500 |

|

3-10 |

0.501-0.625 |

4-5 |

0.251-0.312 |

5-8 |

0.376-0.500 |

6-8 |

0.376-0.500 |

8-10 |

0.501-0.625 |

|

4-6 |

0.313-0.375 |

5-10 |

0.501-0.625 |

6-10 |

0.501-0.625 |

8-12 |

0.626-0.750 |

||

|

4-8 |

0.376-0.500 |

5-12 |

0.626-0.750 |

6-12 |

0.626-0.750 |

8-14 |

0.751-0.875 |

||

|

4-10 |

0.501-0.625 |

5-14 |

0.751-0.875 |

6-14 |

0.751-0.875 |

8-16 |

0.876-1.000 |

||

|

4-12 |

0.626-0.750 |

5-16 |

0.876-1.000 |

6-16 |

0.876-1.000 |

8-18 |

1.001-1.125 |

||

|

4-14 |

0.751-0.875 |

5-18 |

1.001-1.125 |

6-18 |

1.001-1.125 |

8-20 |

1.126-1.250 |

||

|

6-20 |

1.126-1.250 |

8-22 |

1.251-1.375 |

||||||

|

6-22 |

1.251-1.375 |

8-24 |

1.376-1.500 |

How to Measure a Rivet

When measuring a rivet, there are three separate measurements required.

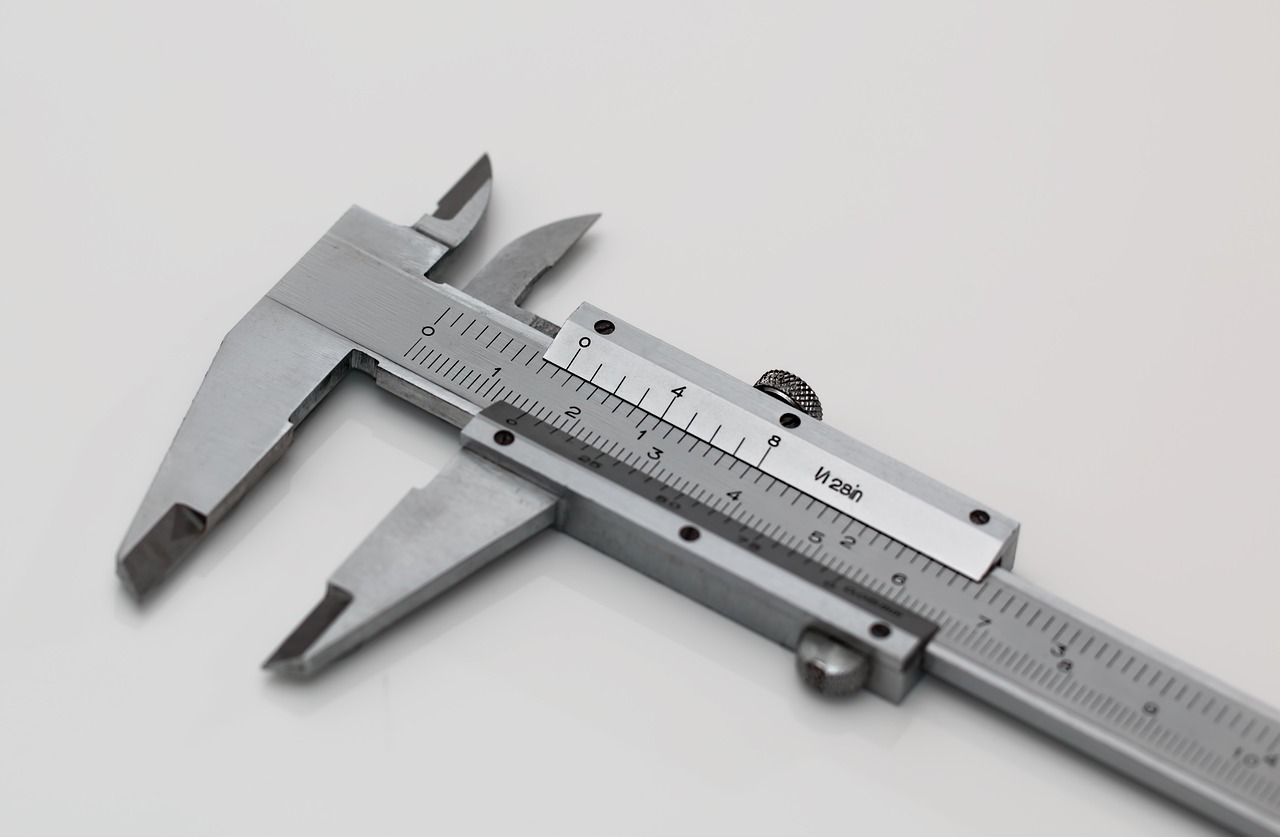

- First, measure the rivet’s diameter (the body, not the mandrel) using a caliper or similar measurement device.

- Next, measure the length of the hat without the mandrel.

- Finally, the grip range is also essential. The length measured above is 1.5 times the rivet’s grip range.

These are the critical parts of the measurement process, but you can easily refer to the size charts above for the relevant information.

Types of Rivets

As you may expect from this kind of versatile tool with so many different uses, there are many different rivet types to choose from. Each of them is slightly different, making them ideal for a whole range of different applications. Below, we’ll briefly discuss each type of rivet:

- Open End Rivets - These are some of the most popular rivets. The mandrel has a domed end which forces the hat open when the rivet is installed.

- Closed End RIvets - These rivets have a sealed end which helps to prevent corrosion or leakage in sensitive applications.

- Multi-Grip Rivets - These rivets have a wider and more variable grip range, making them ideal for applications where the material thickness varies.

- Exploding or Tri-Fold Rivets - These rivets have a bulding hat, and three folds, giving them a wider grip range and greater resistance to pullthrough.

- Structural or Interlock Rivets - These have a stronger locking mechanism, which is why they’re generally recommended for structural applications.

- Painted Head Rivets - These rivets have pre-painted heads, allowing them to blend with the background color of the surface they’re installed on.

Rivet Head Styles

As with the various rivet types, there are also a range of rivet head types, intended for different purposes and materials. Let’s take a closer look.

- Dome Head - One of the most common types, dome head rivets have an exposed, rounded head.

- Countersunk Head - Countersunk head rivets sit as close to flush as possible, in complete contrast with dome head rivets.

- Low Profile or Flat Head - Flat head rivets sit slightly higher than countersunk rivets.

- Large Flange Head - These rivets have larger heads, distributing the surface pressure more evenly and offering greater resistance to pullthrough.

- Shave Head - The mandrels on these rivets don’t snap flush with the hat, which means they have to be trimmed and filed after installation.

Rivet Tools & How to Use Them

With so many different rivets and rivet head types to choose from, it’s only expected that there’d be a range of tools and rivet guns as well. Let’s take a closer look:

- Hand Riveters- Hand riveters are a common choice for DIY installations. One or two squeezes of the trigger or handle usually finish the installation.

- Lever Riveters - These are slightly more robust, with two handles that allow you to apply more force and install stronger rivet types.

- Battery Powered Riveters - These are handheld, wireless, electric riveters that pull the mandrel when you press the trigger.

- Pneumatic Riveters - Pneumatic riveters use compressed air to quickly and efficiently install rivets when you press the trigger.

Removing a Rivet

Installing a pop rivet is a simple process. However, these fasteners are intended to be used permanently. While they are quick and easy to install, they’re a lot harder to remove.

If the occasion arises when you absolutely have to remove a blind rivet, you have three different options.

Removing a Pop Rivet With a Drill

Probably the easiest way to remove an installed pop rivet is to drill it out. Here’s how:

- Step One: Set up your drill (a lower-power or battery-operated drill is a good option since it will be easier to control) with a steel drill bit of the same size as your initial hole for fastening. Ensure that you choose a drill bit intended for drilling through metal.

- Step Two: Align the drill bit with the center of the blind pop rivet’s hat. This is essential to avoid damaging the fastened materials while removing the rivet.

- Step Three: Activate the drill, and apply slow, even pressure to the rivet, allowing the drill bit to pierce the center of the rivet and slowly enlarge the hole. Try not to make the drill go too fast, and never use the hammer function on the drill.

- Step Five: Keep the drill as straight as you can and apply constant pressure to the rivet while running it. Drilling through the rivet's body shouldn’t take more than a minute. If it takes a long time without seeing much progress, you’re probably using an inappropriate drill bit.

- Step Six: Keep drilling till the bit passes through the rivet. Once it does, you’ll have removed the rivet’s locking mechanism and can simply remove the rest of the cap using a flat screwdriver or a pair of tongs.

- Pro Tip: If a rivet starts spinning while you're drilling it, stop and tape it down with a blue painter or duct tape. That should hold it in place while you finish drilling.

That’s how easy it is to remove a blind rivet with a drill. You can repeat this process as many times as necessary to ensure that all the required rivets have been removed from the fastened surface.

Removing a Blind Rivet With a Grinder

Another fairly simple way of removing rivets, although it can be somewhat harder to control the device, is by using a grinder.

As with the drill, we recommend using a smaller, lower-powered device like a battery-powered angle grinder. This will help you control the device more easily and prevent damage to the fastened materials.

Here’s how to remove a blind pop rivet using an angle grinder:

- Step One: Ensure that your grinder is equipped with an appropriate grinding disc for metal rather than one intended for sanding or something like a flap disc.

- Step Two: Activate the grinder and gently run it along the rivet’s hat until the hat is entirely removed and only the rivet's body remains within the hole.

- Pro Tip: When running the angle grinder across the rivet, try to avoid holding the grinder at a horizontal angle. Instead, try to keep it more or less vertical (in parallel with the fastened surface). Doing so allows you to run the very edge of the grinder disc, or even the flat of the disc, along the rivet, minimizing damage to the fastened surface.

- Step Three: Use a hammer, along with a screwdriver, pin, or awl, to knock out the rivet's body so it is no longer seated inside the hole.

- Step Four: Use an appropriate tool (depending on the material) to sand off or finish the fastened material and remove any gouges or gashes left by the removal process. Consider treating the surface as required to ensure that it doesn’t rust, rot, or suffer other issues as a result.

As you can see, removing pop rivets with a grinder is fairly simple. However, unless you’re very methodical and take your time with the removal process, it can damage the surface beneath the rivet.

If you’re not careful, you can easily grind straight through the fastened surfaces rather than simply removing the grinder. So, if you do decide to use this technique, try to be as careful as possible.

Removing a Blind Rivet With a Hammer and Screwdriver or Chisel

If you don’t have access to either a drill or a grinder, you can always try to remove the pop rivet with hand tools.

This is an effective technique, but, as with the grinder, it may damage the work surface. If you have an option, it’s usually best to drill out the pop rivets, as this is the technique that’s least likely to damage the work surface when done properly.

Here’s how to remove a blind rivet with hand tools:

- Step One: Gather all the tools you need. You’ll need a smallish hammer, like a ball peen since you don’t want to damage the work surface more than necessary. You also need a flat screwdriver or chisel and a screwdriver, pin, or awl for removing the rivet’s body.

- Step Two: Align the edge of the screwdriver or chisel with the rivet's cap. Angle the tool slightly so that it can slip underneath the cap.

- Step Three: Use the hammer to tap the screwdriver or chisel so that it collides with the rivet’s cap. You want to be firm but not overly forceful.

- Step Four: One of two things may happen at this point. Either the rivet’s cap may come off entirely (if you managed to get the angle and the amount of force just right), or the chisel or screwdriver may slip in under the rivet’s cap. If the latter happens, tap the tool with the hammer again until the cap comes off. If the former, put aside your chisel.

- Step Five: Align the tool you’ve chosen for removing the rivet’s body (awl, pin, or screwdriver) with the rivet body in the hole. Tap the tool with the hammer to eject the rivet body from the other side of the work surface.

- Step Six (optional): Use sandpaper, a flap disc, or another form of finishing tool to remove the gashes and gouges you’ve unintentionally placed in the work surface while removing the pop rivet.

As you can see, removing a blind rivet or pop rivet with hand tools is entirely accomplishable. It is an efficient way to remove rivets, but it’s more likely to cause unintentional damage than drilling the rivet out would be.

That said, if hand tools are all you have available, you can remove rivets this way. Just ensure that you have tools on hand for repairing and restoring the surface as needed.

As with the other techniques, you can repeat this method as many times as needed to separate the two joined materials.

Choosing the Right Rivet for Your Application

At this point in the article, we’ve gone from asking, “What are blind rivets?” to asking, “Which blind rivets should I use?”

The main things you need to consider are the following:

- Materials

- Rivet Material

- Head Type

- Rivet Diameter

- Grip Range

All of the size aspects have been fully discussed earlier in the article, so you can simply refer to the charts provided. Remember to purchase rivets with a diameter that matches the application. For large areas, consider larger diameter rivets, and vice versa.

When looking for the right rivet, simply choose a rivet material that matches the material you want to use it on and the application. For example, if you are installing a basin on a kitchen counter, you will want stainless steel rivets to prevent corrosion.

If you work with soft, malleable materials that are at low risk of corrosion, you can opt for a less hardy rivet material.

Conclusion

As you can see, pop rivets are less complex than you may have imagined initially. The key is to ensure that you drill appropriate-sized holes for your rivets and that they have enough grip range to meet your needs.

We hope that you now find yourself prepared to use these simple fasteners in your own projects.