How to Repair Loose or Damaged Rivets?

Rivets are a common method of fastening materials together and can be found in many items, from furniture to boats. If your rivets have become loose or damaged, there are several ways to repair them.

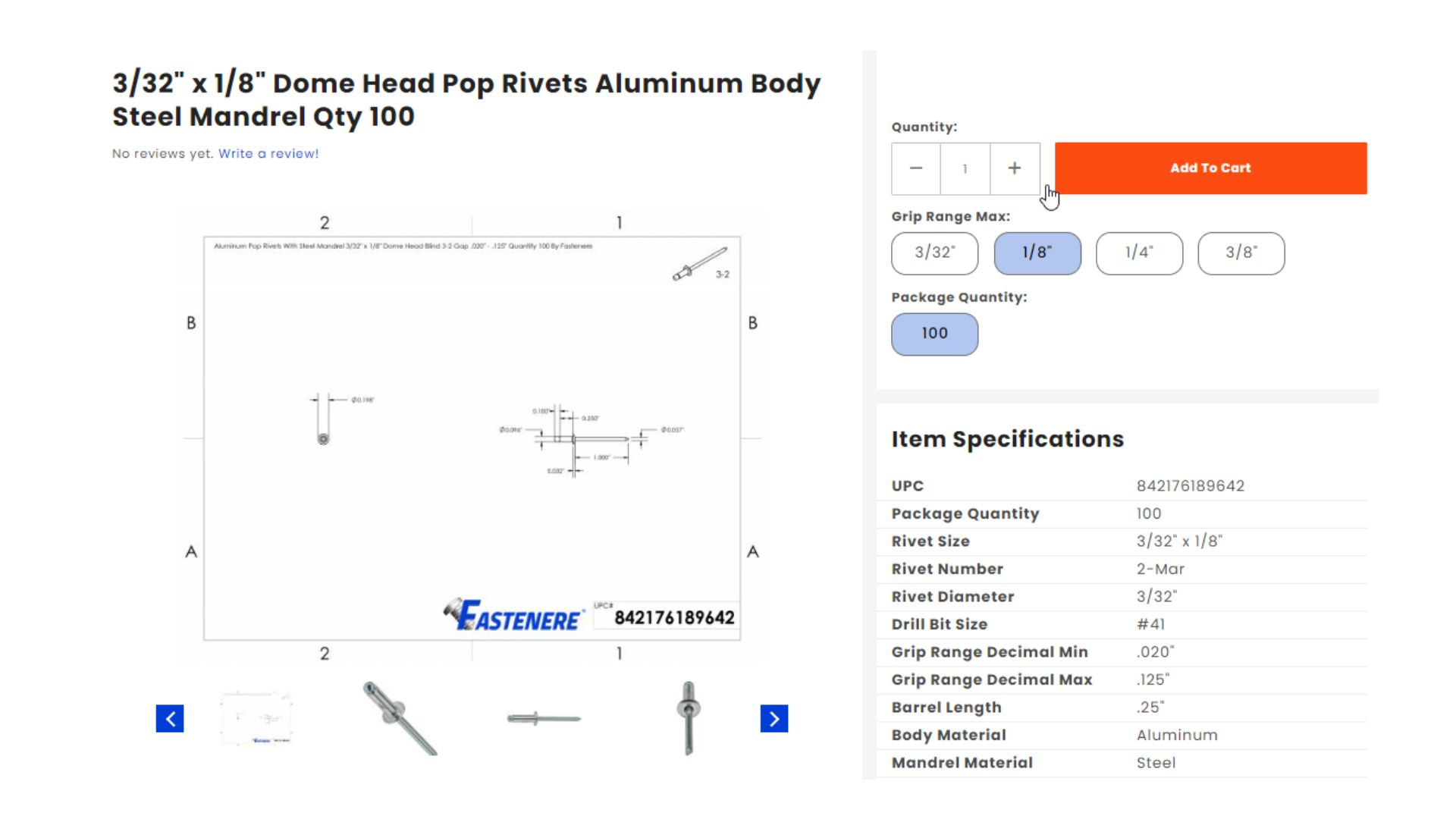

The first step is to determine the type of rivet you have. There are three main types: pop rivets, blind rivets, and solid rivets. Pop rivets have a stem that breaks off, while blind rivets are inserted from one side of the material and remain hidden. Solid rivets require a hole to be drilled into both materials being joined together.

Once you've identified the type of rivet you have, it's time to start the repair process. For pop rivets, you'll need to drill out the old rivet and replace it with a new one. This can be done using an electric drill and a bit that's slightly larger than the diameter of the rivet stem. Once the hole is drilled, insert the new pop rivet into it, then use a hammer or other tool to flatten the stem.

Restoring rivet integrity: Expert tips for repairing damaged fasteners

To be sure your rivets are secure and long-lasting, you should carefully examine them from time to time for signs of damage. If you find any damaged fasteners, here are some expert tips for repairing the rivets:

1. Don’t slap together a quick fix with inadequate adhesives or sealants—this may cause more damage down the road.

2. If there’s corrosion on the rivet, use a wire brush to remove it before repair or replacement begins.

3. Once all corrosion is removed, you can replace the damaged rivets with new ones of the same dimensions and material as the original fastener.

4. If the material surrounding the rivet is damaged, you may need to cut or drill out a larger hole to accommodate a new fastener.

5. Before inserting a new rivet, apply anti-seize lubricant to ensure it stays secure and doesn’t corrode further down the line.

6. Once the new rivet is in place, be sure to secure it with an appropriate amount of pressure. This will ensure that the fastener is tight and won’t move or come loose over time.

If you have a pop rivet, blind rivet, or solid rivet that needs repair, contact your local hardware store for the proper tools and materials.

DIY solutions for repairing loose or failed rivets in different materials

If you’ve got loose or failed rivets in different materials, such as wood, metal, plastics, and composites, there are a few good DIY solutions. For wood applications, use an epoxy adhesive to secure the fastener back into place. If the material is metal, you can either weld or solder the joint area and add a nut and bolt fastener to make the connection more secure.

Knowing how to repair any kind of loose or failed rivets like pop rivets is essential for many projects involving metal, wood, plastics, and composites. With some basic tools and a bit of elbow grease, you can easily repair and restore your items with secure fasteners.

Troubleshooting loose rivets: Common causes and effective remedies

Loose rivets are often caused by improper installation, corrosion, or weakening of the material around the fastener. If you have any loose rivets on any kind of rivets like dome head rivets that need attention, there are a few possible causes and effective remedies to consider.

First, check the material used for the application. If it’s a soft metal like aluminum, it may be too weak to hold the fasteners in place. You can remedy this by drilling larger holes or using self-tapping screws that are better suited for softer materials.

Next, inspect the rivets for corrosion. If you find any corroded parts, clean them with a wire brush before attempting any repairs. Corroded fasteners can weaken over time and further damage the materials being connected.

Finally, check to make sure the rivets were installed properly. If they weren’t tightened enough or if there are any gaps in the parts, you may need to redo the installation.

Rejuvenating loose or damaged rivets: Techniques for a secure fix

When it comes to restoring any kind of rivet like pop rivets, blind rivets, stainless steel rivets/stainless rivets, countersunk rivets, friction lock rivets, semi tubular rivets, copper rivets, brass rivets, countersink rivets, bifurcated rivets, flush rivets, self piercing rivets, split rivets, solid rivets, and more, the key is to use techniques that will ensure a secure fix. Here are some tips for rejuvenating loose or damaged rivets:

1. If you need to replace any of the fasteners, make sure you use ones with the same dimensions and material as the original rivet.

2. Before inserting a new rivet, apply anti-seize lubricant to help ensure it won’t corrode further down the line.

3. Use an appropriate amount of pressure when installing blind rivets or any kind of rivets and be sure to use a backing plate on the opposite side for additional support.

4. If the material around the rivet is damaged, you may need to enlarge the hole to accommodate a new fastener.

Following these tips will help ensure that your rivets remain secure and long-lasting—saving you time and money in the long run.

Rivet repair methods for optimal structural strength and durability

When it comes to steel rivets repair, the goal should always be to achieve optimal structural strength and durability. Here are some methods to follow when repairing any kind of rivets:

1. Have a plan: When working on a rivet repair project, it’s important to have a specific plan in mind for how you’ll approach the repair. Make sure you have all the necessary tools and materials for a successful job, and be aware of any safety risks before you begin.

2. Choose the right rivet: Different types of rivets are best used in different applications. Be sure to select one that is suited to the material being joined together and the strength requirements of the application.

3. Pay attention to detail: Carefully inspect all rivets for corrosion, signs of wear or damage, and any other issues before attempting a repair.

4. Work in an organized manner: When working on a rivet repair project, make sure you’re organized and take your time. This will help to ensure that any repairs are done properly and securely.

If you’re ever unsure of how to proceed with a repair project, contact an experienced professional for assistance.

Quick fixes for loose rivets: Temporary and permanent repair options

Sometimes, a quick fix may be necessary for any kind of loose rivets like aluminum pop rivets, blind rivets, pop rivets, and solid rivets that need attention. You have two main options to choose from: a temporary repair, or a more permanent solution.

For a temporary fix, you can use a sealant or adhesive to secure the rivet back into place until you’re able to replace it with a new one. This is only recommended for small jobs, as it may not provide adequate strength or protection for longer-term applications.

For a permanent repair, you’ll need to replace the rivet with a new one of the same size and material as the original fastener. This is generally the best option for most jobs, as it will ensure that your items remain securely attached for years to come.

Reviving loose rivets: Tools, techniques, and troubleshooting tips

Reviving loose rivets can be a tricky job if you don’t have the right tools or techniques. You can easily repair any kind of fastener with the right tools and a bit of know-how.

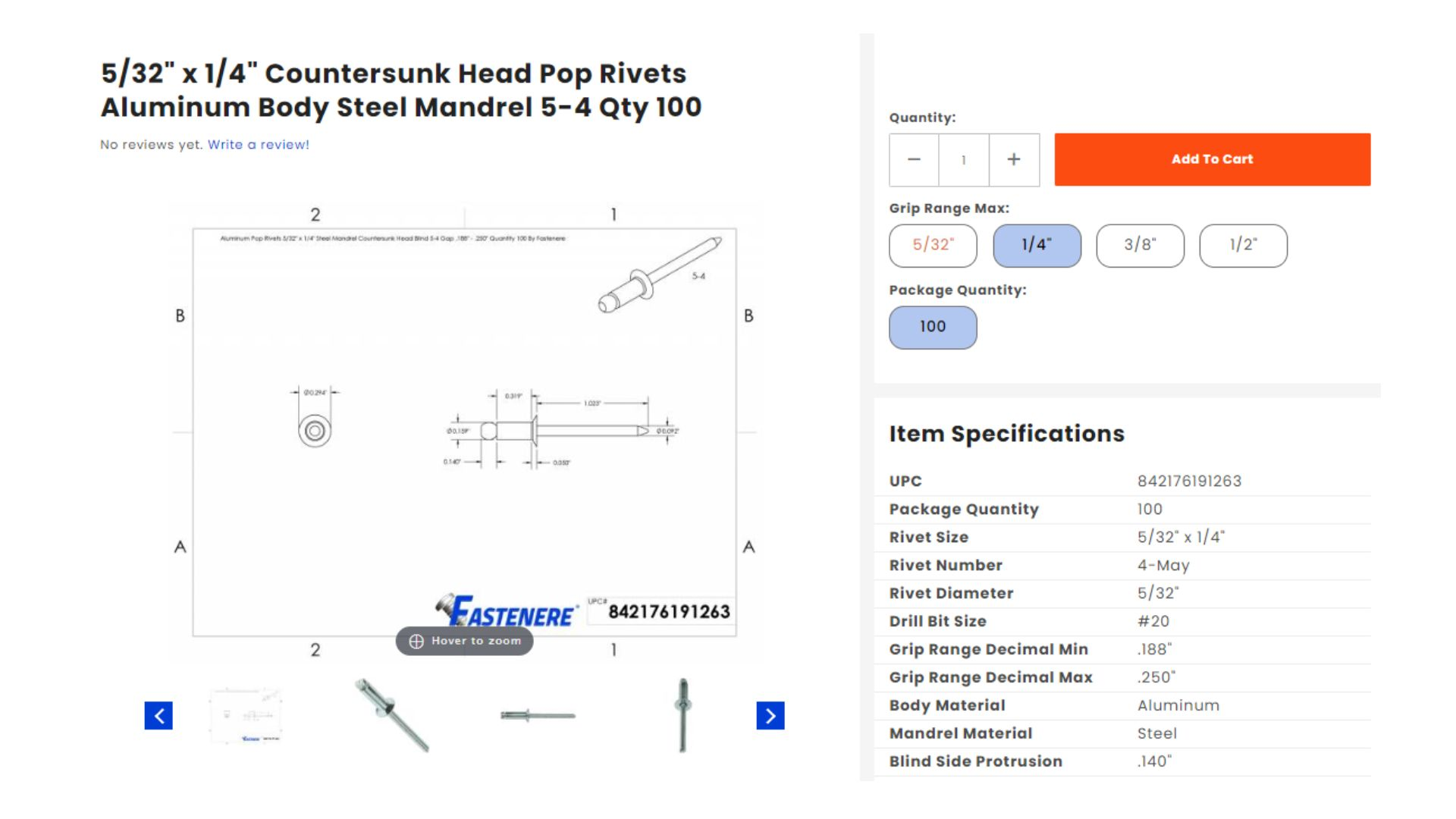

- First, use a wire brush to remove any corrosion from the countersunk head pop rivets.

- Then, select a new fastener that’s of the same size and material as the original one and use an appropriate amount of pressure when installing it into place.

- Lastly, if you have any damaged materials surrounding the countersunk holes rivet, cut or drill out a larger hole to accommodate the new mechanical fastener.

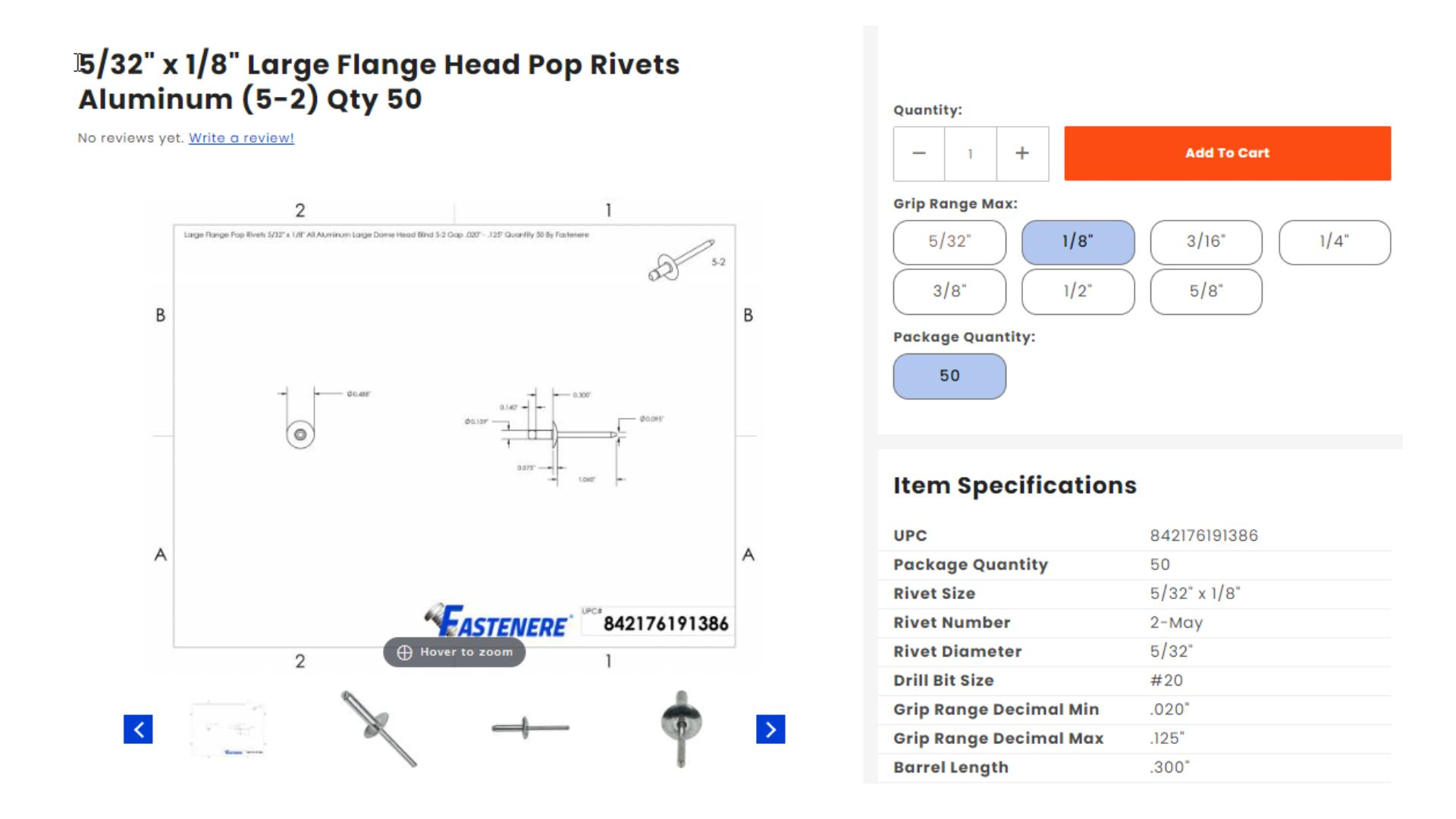

Repairing damaged rivets: Approaches for different materials and applications

Depending on the material and application, there are several approaches to repairing any kind of damaged rivets like large flange aluminum rivets. If you’re working with wood or metallic pin, you can use a combination of welding and soldering for a secure fit. For plastic or composite materials, two-part epoxy adhesives or contact cement may be used instead.

If the material around the rivet is damaged, you may need to drill out a larger hole to accommodate the new fastener. In addition, be sure to use an appropriate amount of pressure when installing blind rivets or any kind of rivets. This will ensure that they stay secure and won’t move or come loose over time.

Fixing loose rivets: Step-by-step repair guide for various applications

If you’ve got loose or failed pop rivets or any kind of rivets in different materials, such as wood, metal, plastics, and composites, you can do the steps as what was stated in the previous question. It's best to have a specific plan in mind for how you’ll approach the repair and ensure that you have all the necessary tools and materials for a successful job. By reading this whole article, it will be a great help for you to understand the process better.

FAQs

How do I identify the type of rivet for repair?

Identify the rivet type (pop, blind, solid) before repair. Pop rivets have a break-off stem, blind rivets are inserted from one side, and solid rivets require drilling into both materials.

What steps are needed to replace a loose pop rivet?

Drill out the old rivet, insert a new one, and flatten the stem using a hammer or tool. Use a bit slightly larger than the rivet's diameter for drilling.

What are the best practices for repairing damaged rivets?

- Use anti-seize lubricant before inserting a new rivet.

- Replace damaged rivets with ones of the same size and material.

- Ensure proper pressure when securing the rivet for a tight fit.

- Clean corrosion with a wire brush before replacement.

What are temporary and permanent fixes for loose rivets?

Temporary fix: Use adhesive or sealant to hold the rivet in place temporarily.

Permanent fix: Replace the rivet with a new one of the same size and material.

What tools and techniques should I use for rivet repair?

Use a wire brush to clean corrosion, and select a new rivet of the same dimensions. Apply appropriate pressure during installation and, if needed, enlarge the hole to accommodate the new fastener.

How can I address rivet issues in different materials?

- For wood: Use epoxy adhesive to secure the rivet.

- For metal: Weld or solder for a secure fix.

- For plastics/composites: Use two-part epoxy adhesives or contact cement.

How do I ensure my rivets stay secure?

Regularly inspect rivets for damage, use proper installation techniques, and apply anti-corrosion measures to ensure long-lasting strength and stability.